Release time: July 02, 2024

Views: 677

In today's fast-paced world, lasers have become indispensable across various industries, revolutionizing the way we display, manufacture, and innovate. From captivating visual experiences in cinemas to precision engineering in manufacturing facilities, lasers offer unparalleled capabilities, driving efficiency, and productivity. However, to maintain their efficiency and longevity, laser systems require meticulous temperature management, underscoring the importance of advanced laser cooling technology.

The Science and Significance of Laser Cooling

Laser technology has revolutionized various industries, offering unparalleled precision and efficiency in a wide range of applications. From entertainment to manufacturing, lasers are integral to processes that demand high performance and reliability. However, efficient temperature management is crucial for optimizing laser systems' performance and longevity, underscoring the significance of advanced laser cooling technology.

Understanding Laser Cooling

High-power laser diodes, essential components of laser systems, generate substantial heat during operation due to inefficiencies in energy conversion. This heat accumulation poses challenges to system performance and component longevity. Thermoelectric cooling, utilizing the Peltier effect discovered by Jean Charles Athanase Peltier in 1834, addresses these challenges. By passing an electric current through dissimilar semiconductor materials, thermoelectric coolers create a temperature gradient across the junction, enabling precise temperature control and heat dissipation in laser systems.

Applications in Entertainment and Industrial Settings

Laser projection systems have transformed the entertainment industry, offering vibrant visuals and immersive experiences in cinemas, concerts, and theme parks. These systems rely on high-power laser diodes to generate intense light for projection. However, the efficient management of heat generated during operation is critical for ensuring optimal performance and longevity.

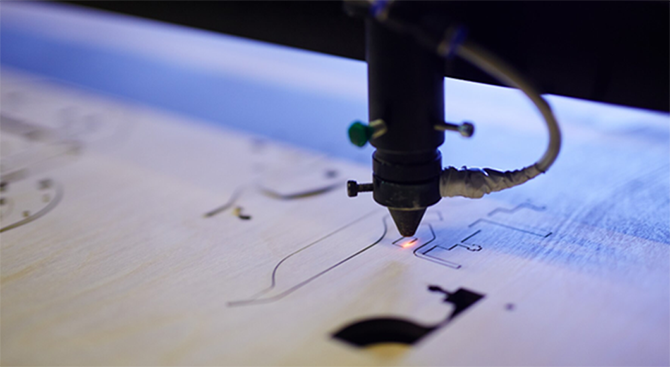

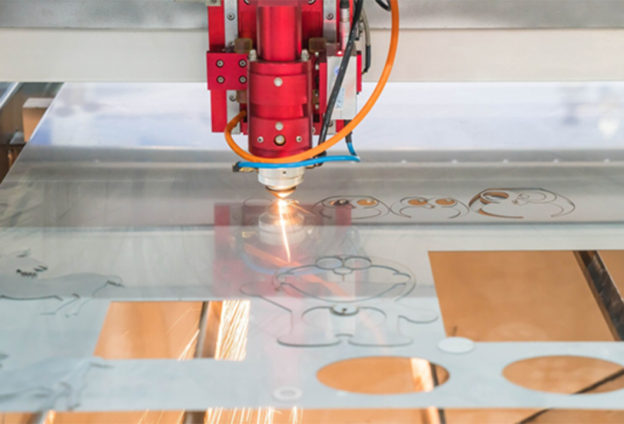

In industrial environments, lasers are indispensable tools for various applications, including cutting, marking, and welding. Laser cutting systems deliver precision and efficiency in metal fabrication, automotive manufacturing, and aerospace industries. Laser marking equipment ensures product traceability and identification in packaging and manufacturing processes. Additionally, lasers play critical roles in medical device manufacturing, electronics production, and research laboratories.

Benefits of Effective Thermoelectric Coolers

Benefits of Effective Thermoelectric Coolers

Effective thermoelectric coolers offer a range of benefits across various applications, including entertainment and industrial settings:

Enhanced Performance

In laser projection systems, thermoelectric coolers maintain optimal temperatures, significantly improving efficiency and output quality. Whether delivering high-definition visuals in cinemas or facilitating critical presentations in boardrooms, consistent performance is essential for impactful experiences. Similarly, in industrial laser cutting and marking applications, precise temperature control ensures the accuracy and quality of the finished products, enhancing customer satisfaction and operational efficiency.

Increased Lifespan

Efficient cooling provided by thermoelectric coolers prevents overheating and extends the operational lifespan of laser diodes. By dissipating excess heat, these coolers mitigate the risk of thermal degradation and premature component failure, reducing maintenance costs and ensuring uninterrupted system usage over time. This enhanced durability translates to improved return on investment and operational efficiency across entertainment venues and industrial facilities alike.

Consistent Output

Stability is crucial in precision applications such as medical imaging or engineering design. Thermoelectric coolers maintain stable temperatures within laser projection systems and industrial laser equipment, ensuring consistent output over prolonged periods. By minimizing the impact of external factors, such as ambient temperature variations, these coolers enable reliable performance in critical scenarios, fostering trust among users and facilitating seamless integration into professional environments.

In summary, effective thermoelectric coolers offer key advantages for laser projection systems. By maintaining optimal temperatures and ensuring reliable operation, these coolers contribute to delivering captivating visual experiences and driving success across diverse industries.

Huajing's Peltier Based Coolers For Laser Systems

Huajing, a leading provider of thermoelectric cooler assemblies, offers cutting-edge solutions tailored for a wide range of industrial laser systems. Here are the key advantages of Huajing's thermal management solutions:

1. Compact Structure: Huajing's thermoelectric cooler assemblies boast a compact structure, allowing for seamless integration into various systems without occupying excessive space. This ensures flexibility in design and installation, catering to diverse application requirements. Whether it's for laser cutting, welding, or engraving systems, the compact design facilitates efficient space utilization and optimal performance.

2. Customized Design: Recognizing the unique needs of different clients, Huajing provides customized design options for its cooler assemblies, considering factors such as size constraints, specific performance criteria, heat dissipation methods, and structure. Whether clients require compact solutions for space-limited environments or robust cooling capabilities for high-performance applications, Huajing's tailored designs optimize the efficiency and reliability of their laser systems.

3. Reliable Performance: With a relentless focus on quality and reliability, Huajing's cooler assemblies are engineered to deliver consistent performance in challenging environments. From extreme temperatures to demanding usage scenarios, these assemblies uphold their efficiency and effectiveness, minimizing downtime and maximizing productivity. This reliability is crucial for industrial lasers used in precision manufacturing, where consistent performance directly impacts product quality and operational efficiency.

Conclusion

In conclusion, laser cooling technology plays a pivotal role in enhancing the performance and longevity of laser systems across diverse applications. By effectively managing temperatures, thermoelectric coolers ensure optimal operation, reliability, and output quality, thereby elevating the overall user experience in cinemas, manufacturing facilities, and research laboratories. With Huajing's advanced Peltier-based coolers, businesses can unlock the full potential of their laser systems, setting new standards for efficiency and performance in various industries.

Looking for more

information?

0755 23405284

Email: sale02@hj-tc.com

Add: 3/F No.5 Building,Yesun Pingshan Life and Health Technology Park, No. 19 Linhui Road,Pingshan District, Shenzhen, Guangdong,CN.

©2019- 2024 Huajing Co.,Ltd.Copyright