Release time: November 22, 2024

Views: 568

The Peltier Effect is an interesting phenomenon. It’s a solid-state, electrical-based method that enables precise heating and cooling that forms the basis of countless electronics, devices, and industrial systems. While discovered about two centuries ago, its applications in today’s world are significant. This article provides an overview of the Peltier Effect principle and reviews its widespread uses.

The Peltier Effect: Overview

The Peltier Effect refers to the heating or cooling of a material when electric current flows through it. The French physicist Jean Peltier, observed it first in 1834. He noticed an electric current passed through two dissimilar conductors, causing one junction to heat up and the other to cool down.

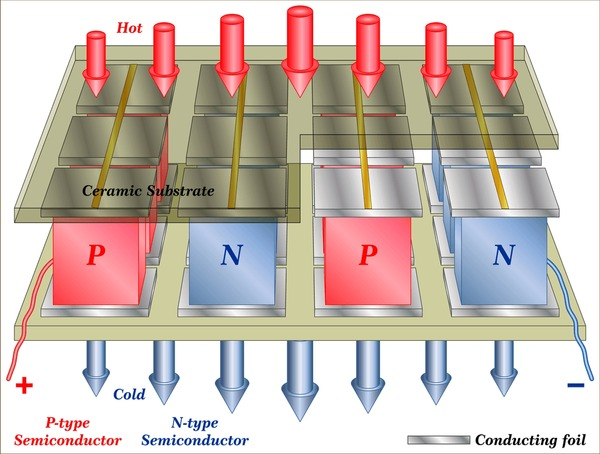

The Peltier Effect principle is straightforward. Charge carriers flow between two different conductors or semiconductors; they either gain or lose energy during this process. This outcome depends on the amount of work needed to move them over the potential barrier at the junction, the Fermi levels of the two materials are not aligned. As the charge carriers move, they transport heat with them. This causes one junction side to increase in temperature and the other to decrease.

At the junction between two different conductors or semiconductors, heat will either be absorbed or released. This depends on the direction of the electric current. When current flows in one direction, heat is absorbed at one junction. It is dissipated at the other junction at the same time. When the current direction is reversed, the heating and cooling functions switch at the two junctions. This allows precise control over the temperatures at the junction interfaces.

Applications of the Peltier Effect

By leveraging its solid-state capability to both heat and cool, the Peltier Effect enables diverse applications across multiple industries. These include:

1. Cooling Systems

The Peltier Effect finds wide use in cooling electronic devices and circuitry. Peltier modules help efficiently dissipate heat produced by chips in computers, servers, and other systems to maintain optimum performance.

2. Heating Systems

In industries, localized heating devices based on the Peltier Effect carry out tasks like soldering through compact thermoelectric heaters. Consumer products also utilize portable heaters.

3. Power Generation

By converting temperature differences into electric current, thermoelectric generators harness wasted heat for power. The Peltier Effect is utilized in spacecraft systems to provide power for onboard instruments and communication systems.

4. Other Niche Applications

Thermoelectric modules leveraging the Peltier technology have many other niche applications. They are used as crucial components in scientific test equipment and space technology requiring climate control, etc.

Peltier Modules and Their Components

Peltier modules are at the core of utilizing the Peltier Effect for temperature control. These consist of essential components integrated to provide heating and cooling through electricity.

1. Structure and Design of Peltier Modules

Peltier modules contain semiconductors sandwiched between two ceramic plates, which are typically made of materials like bismuth telluride. When current flows, one plate absorbs heat while the other dissipates it. Larger modules can transfer higher heat amounts.

2. Types of Materials Used in Peltier Modules

Common semiconductors used include bismuth telluride (Bi2Te3) and antimony telluride (Sb2Te3) due to their relatively high thermoelectric effect. Newer materials expand the temperature range and efficiency.

3. Efficiency and Performance Factors of Peltier Modules

Key considerations are material selection, design optimization, and module sizing. Larger surface area and thickness increase heat transfer but lower efficiency due to greater power needs. Overall design affects optimal operating temperatures as well.

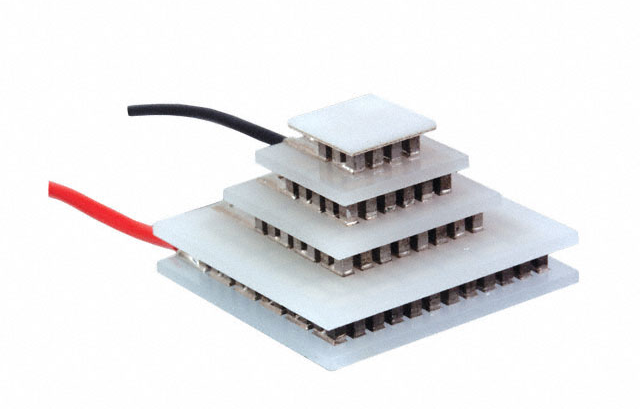

Huajing’s Peltier Modules

Huajing is a leading provider of temperature control technologies with a focus on high quality and customer satisfaction. With years of experience in semiconductor cooling, we design reliable Peltier devices. For example, our TEF1-050XFA Peltier module meets needs for instrumentation, medical, and other precision temperature control applications. The compact Peltier effect cooler design delivers strong performance for efficient heating and cooling. It boasts:

√High temperature control accuracy

√ Fast response speed

√Easy setup and maintenance

√Small, lightweight packaging

√Long product lifespan and reliability with break-proof structure

Our TEF1-050XFA consistently maintains temperatures within narrow ranges. Its rapid temperature change capabilities also satisfy the need for responsive heating or cooling on demand.

Conclusion

The Peltier Effect enables both heating and cooling functionalities through the principles of thermoelectricity and its applications continue growing across different industries. At Huajing, we design reliable Peltier modules and thermoelectric assemblies with strict quality control. Users can rely on our economical and high-performance solutions to meet their temperature control needs. Visit our website to learn more about our broad product range and customized solutions!

Looking for more

information?

0755 23405284

Email: sale02@hj-tc.com

Add: 3/F No.5 Building,Yesun Pingshan Life and Health Technology Park, No. 19 Linhui Road,Pingshan District, Shenzhen, Guangdong,CN.

©2019- 2024 Huajing Co.,Ltd.Copyright