Application of thermoelectric cooler assemblies in wine cabinets mainly involves temperature control and energy utilization. Thermoelectric components, also known as thermoelectric modules or Peltier elements, are devices based on the thermoelectric effect that can convert electrical energy into heat energy and vice versa.

1, Temperature regulation: Thermoelectric components can perform cooling and heating functions, making them suitable for regulating the temperature inside wine cabinets. This is crucial for storing wines and other alcoholic beverages as stable temperature control helps maintain the quality and taste of the wines.

2, Temperature balance: Temperature imbalances may occur within wine cabinets, with some areas being warmer while others are cooler. Thermoelectric components can help balance the temperature, ensuring consistent temperature levels throughout the wine cabinet.

3, Energy efficiency: Compared to traditional refrigeration systems, thermoelectric components have higher energy conversion efficiency. Utilizing thermoelectric components in wine cabinets can lead to reduced energy consumption and achieve energy-saving effects to some extent.

4, Precise control: Thermoelectric components can achieve precise temperature control by adjusting the direction and magnitude of the electric current. This allows the wine cabinet to reach the desired temperature in a shorter time and maintain a constant temperature more easily.

Traditional cooling wine cabinets typically use compression cooling systems, which regulate temperatures by compressing and expanding refrigerants.

1, Flexibility and precise control: Thermoelectric cooler assembly can rapidly and accurately adjust temperatures by changing the direction and magnitude of the electric current. This grants wine cabinets greater flexibility in temperature control, meeting the storage requirements of various types of wines. Precise control is especially important for wines that require frequent temperature adjustments or high-end wines that demand strict storage conditions.

2, Energy-saving effect: Compared to traditional compression cooling systems, thermoelectric cooler assembly have higher energy conversion efficiency. Using thermoelectric components can, therefore, reduce energy consumption to some extent, saving electricity and operating costs.

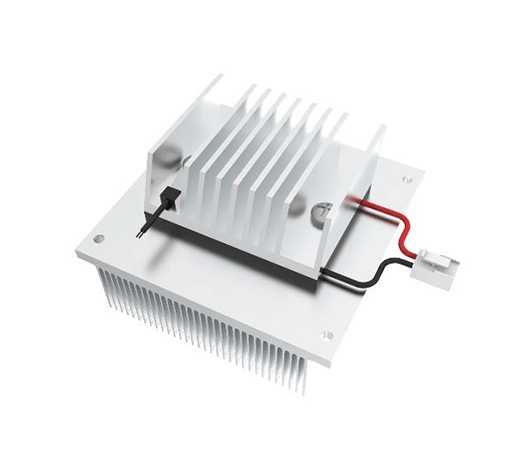

1,Vibration-free and noiseless: Thermoelectric cooling module have no moving parts, ensuring they operate without vibration and noise. This is crucial for storing wines and other sensitive beverages, as vibrations and noise could impact the maturation and quality of the beverages.

3, Compact size: Thermoelectric cooler assembly are relatively small compared to traditional cooling systems, making it easier to integrate them into the design of wine cabinets and saving space.

4, Zero maintenance: Thermoelectric cooling module have no moving parts, resulting in lower maintenance requirements and reduced risk of malfunctions compared to traditional cooling systems.

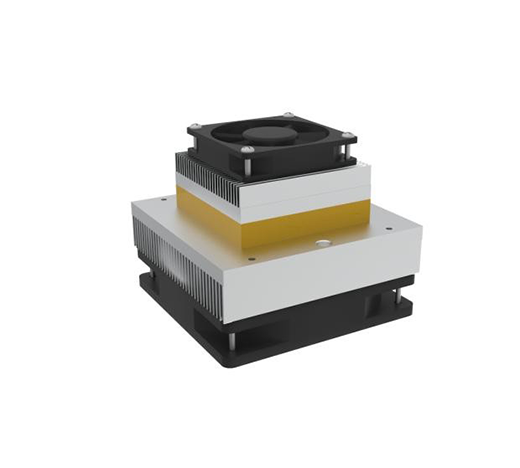

Thermoelectric cooler assemblies are made up of a series of alternating P-type and N-type semiconductors. When an electric current passes through these semiconductors, one side of the P-type semiconductor absorbs heat, while one side of the N-type semiconductor releases heat, creating a temperature difference between the two sides. By changing the direction of the electric current, the direction of heat absorption and release can be altered, enabling cooling or heating. In wine cabinets, thermoelectric cooling module control internal temperature through electric current, absorbing heat to lower the internal temperature or releasing heat to raise it, thus achieving constant temperature storage and preservation for wines.

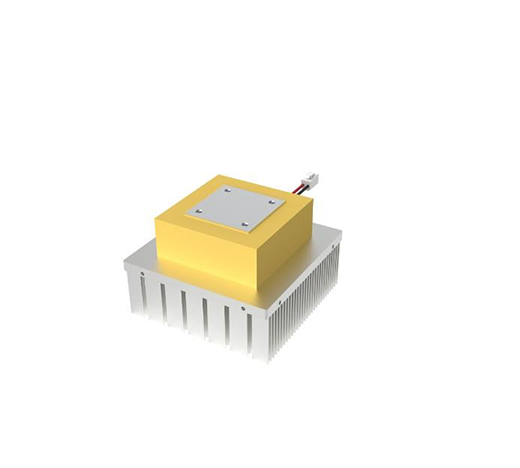

Thermoelectric devices have various applications in beauty cabinets. The thermoelectric effect is a physical phenomenon that converts temperature differences into electrical energy, and thermoelectric modules utilize this effect for temperature regulation and energy conversion.

1, Temperature Control and Adjustment: Beauty cabinets may require maintaining a certain temperature range to preserve the quality and stability of the products inside, such as cosmetics and skincare items. Thermoelectric assemblies can be used to monitor and regulate the internal temperature of the cabinet, ensuring that the products are kept at suitable temperature conditions.

2, Insulation Function: Thermoelectric assemblies can serve as insulation devices, helping the beauty cabinet maintain a constant temperature and avoiding temperature fluctuations that could affect product quality.

3, Refrigeration Function: Certain cosmetics and skincare products need refrigeration to extend their shelf life. By reversing the working principle, thermoelectric modules can transfer heat from the cabinet, achieving a refrigeration effect.

4, Energy Recovery: Beauty cabinets may use electronic devices or lighting, and thermoelectric assemblies can convert the excess heat generated inside the cabinet into electrical energy for recycling and reducing energy waste.

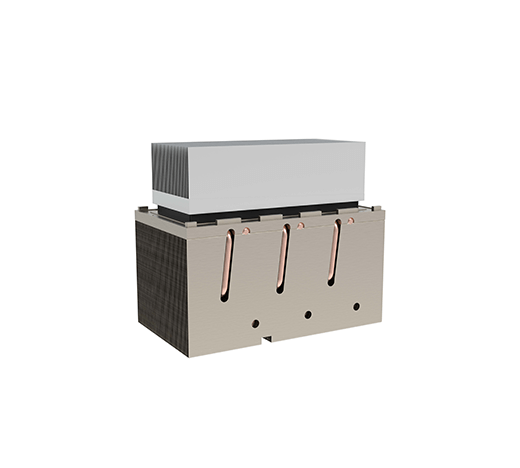

The thermoelectric cooling assembly is a device capable of converting thermal energy and electrical energy into each other. Through this thermoelectric effect, temperature control and regulation can be achieved in dehumidifiers.

1, Temperature Regulation: The performance of dehumidifiers is closely related to the operating temperature. Thermoelectric cooling assembly can be used as temperature controllers to help maintain the dehumidifier within an appropriate working temperature range, thereby improving dehumidification efficiency.

2, Heat Exchange: Dehumidifiers require heat exchange between the condenser and evaporator to achieve the condensation of moist air and the evaporation of dry air. Thermoelectric assembly can play the roles of condenser and evaporator by controlling the direction of the electric current to achieve the condensation of moisture and evaporation of water vapor.

3, Energy Saving: Thermoelectric components can help improve the energy efficiency of dehumidifiers. In some high-end dehumidifiers, thermoelectric assembly are combined with other high-efficiency systems, such as compressors or adsorbents, to make the dehumidifier more energy-efficient.

4, Precision Control: Thermoelectric assembly can achieve precise temperature control by adjusting the magnitude of the electric current. This is useful for achieving precise humidity control under specific environmental conditions.

5, CFC-Free: Compared to traditional refrigerants, thermoelectric cooler assembly do not require the use of CFCs, which gives them an environmental advantage.

The charging box is responsible for storing and charging batteries during drone operations, and high temperatures can have adverse effects on battery performance and lifespan. Thermoelectric cooling devices utilize the thermoelectric effect to achieve temperature regulation, transferring heat from the inside of the charging box to the external environment, thereby keeping the batteries within the appropriate operating temperature range. This device has a simple structure and compact size, capable of rapidly lowering the temperature of the charging box and providing stable cooling effects. By using thermoelectric cooling devices, drone charging boxes can better protect stored batteries and ensure their reliability and performance in high-temperature environments, thereby providing drones with longer flight times and more reliable operations.

The application of thermoelectric cooler assemblies in automotive temperature control cup holders utilizes the thermoelectric effect to achieve temperature regulation and maintenance. This technology is based on the characteristics of thermoelectric materials, where a temperature difference is generated when current passes through the material, resulting in a cooling or heating effect. In automotive temperature control cup holders, thermoelectric cooler assemblies introduce current into the thermoelectric material, causing one side to become cold and the other side to become hot, thereby achieving cooling or heating effects. This technology enables the temperature control cup holder to maintain the appropriate temperature for cold or hot beverages according to the user's needs, providing a comfortable and convenient driving experience. Without the need for external power sources or refrigerants, thermoelectric cooler assemblies offer an efficient and reliable temperature regulation solution in automotive temperature control cup holders, bringing convenience and comfort to users' driving experience.

Our team of temperature control experts will send specialists to

answer your questions one by one.

Looking for more

information?

0755 23405284

Email: sale02@hj-tc.com

Add: 3/F No.5 Building,Yesun Pingshan Life and Health Technology Park, No. 19 Linhui Road,Pingshan District, Shenzhen, Guangdong,CN.

©2019- 2024 Huajing Co.,Ltd.Copyright