Release time: September 15, 2025

Views: 314

The reagent tank is a critical component for storing test reagent kits. Since reagents must typically be preserved within a suitable temperature range, it is particularly important to employ effective thermal management methods to control the air temperature inside the reagent tank.

Biochemical immunoassay diagnostic equipment usually includes a reagent compartment comprising: a cooling chamber, a semiconductor cooling module, and a temperature control system, among others. During sampling and analysis, the equipment draws a certain amount of reagent from the bottles inside the reagent compartment. To ensure the safety of the reagents, the compartment must reach and maintain a temperature between 2°C and 8°C within 30 minutes of startup, achieved through the cooling provided by the semiconductor module and the regulation of the temperature control system.

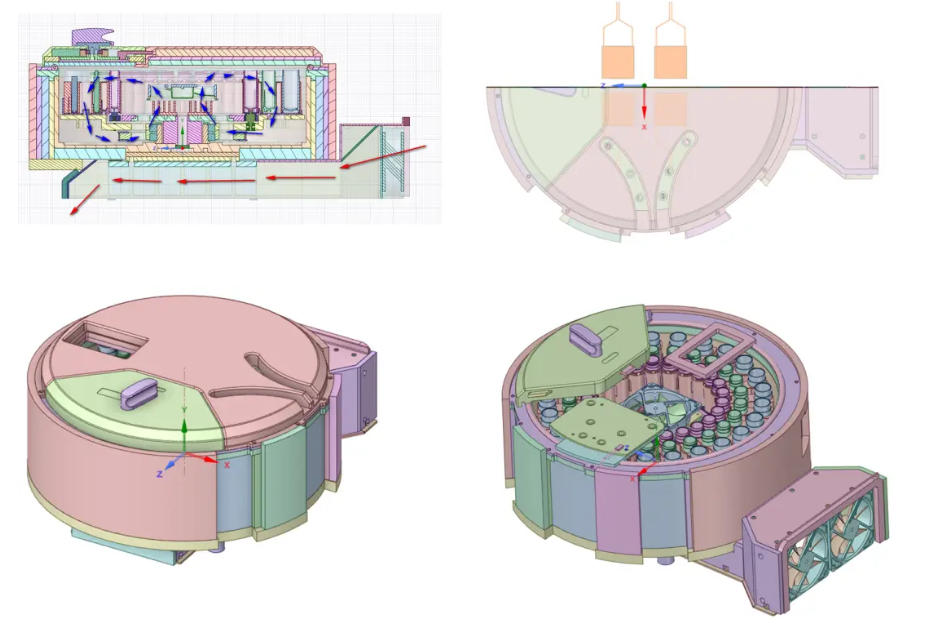

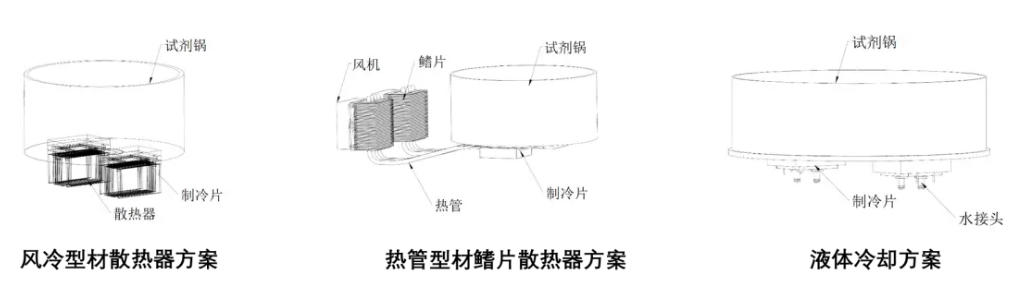

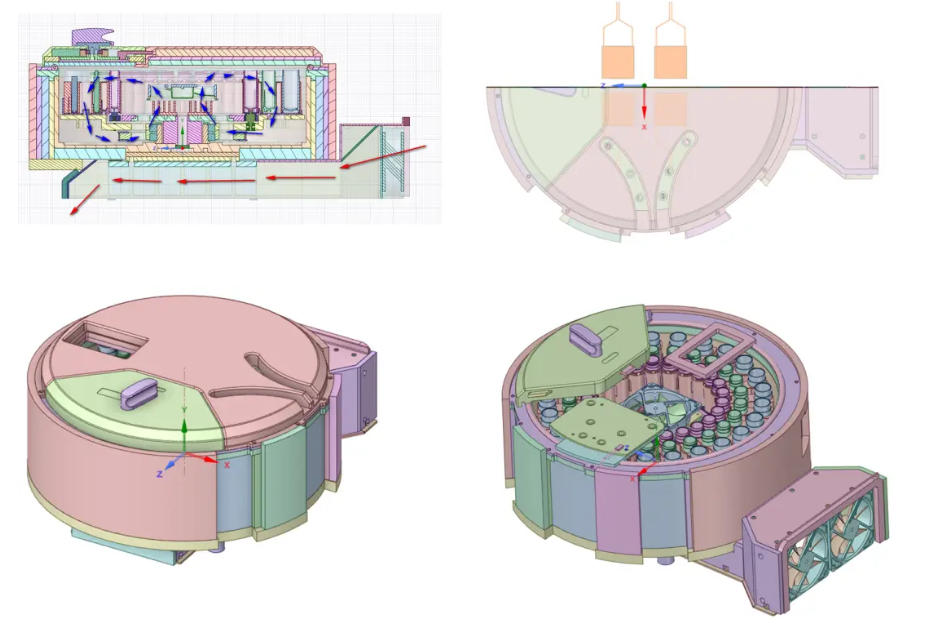

In current reagent compartment temperature control systems, Huajing Temperature Control often employs air cooling and liquid cooling in its semiconductor cooling module designs, with liquid cooling offering higher cooling efficiency. Below is a schematic diagram of a temperature control system solution for the reagent compartment.

Case Study on the Application of Semiconductor Cooling Technology in the IVD Medical Device Industry (Air Cooling Solution)

A fan is installed inside the reagent tank to draw internal air upward, promoting circulation. This allows the colder air (cooled by the TEC) from the lower section to flow upward, thereby contributing to uniform temperature distribution throughout the tank. The lower section houses the heat dissipation control unit, which originally consisted of a TEC, two parallel fans, a fork-fin heatsink, and a sheet metal diversion duct.

Original Structural Model of a Reagent Tank

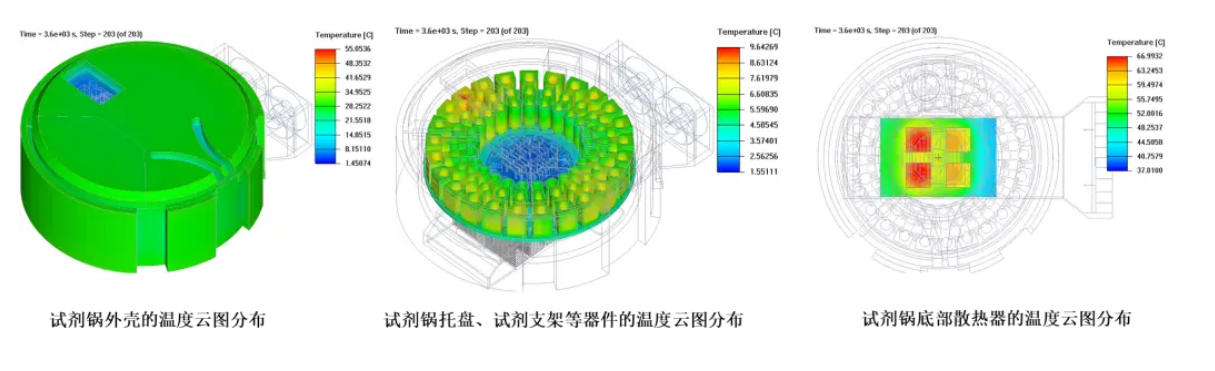

Based on the configuration provided by the client, and considering the actual geometry and the requirements for thermal simulation modeling, structural elements such as screws, nuts, and mounting holes were omitted. Through simulation analysis, the flow field and temperature field of the system were evaluated to simulate the heat dissipation effect of the TEC on the thermal management of the reagent tank. The simulation results are as follows:

From the simulation results, it can be observed that by 2700 seconds, the air temperature inside the reagent tank decreased by approximately 21°C, approaching the target of 8°C. The cold side of the TEC transferred part of the cooling capacity upward to the solid components below the tray. As time progressed, by 2950 seconds, the temperature inside the tank further decreased, reaching 8°C. By 3600 seconds, the air temperature inside the tank dropped further to around 5°C.

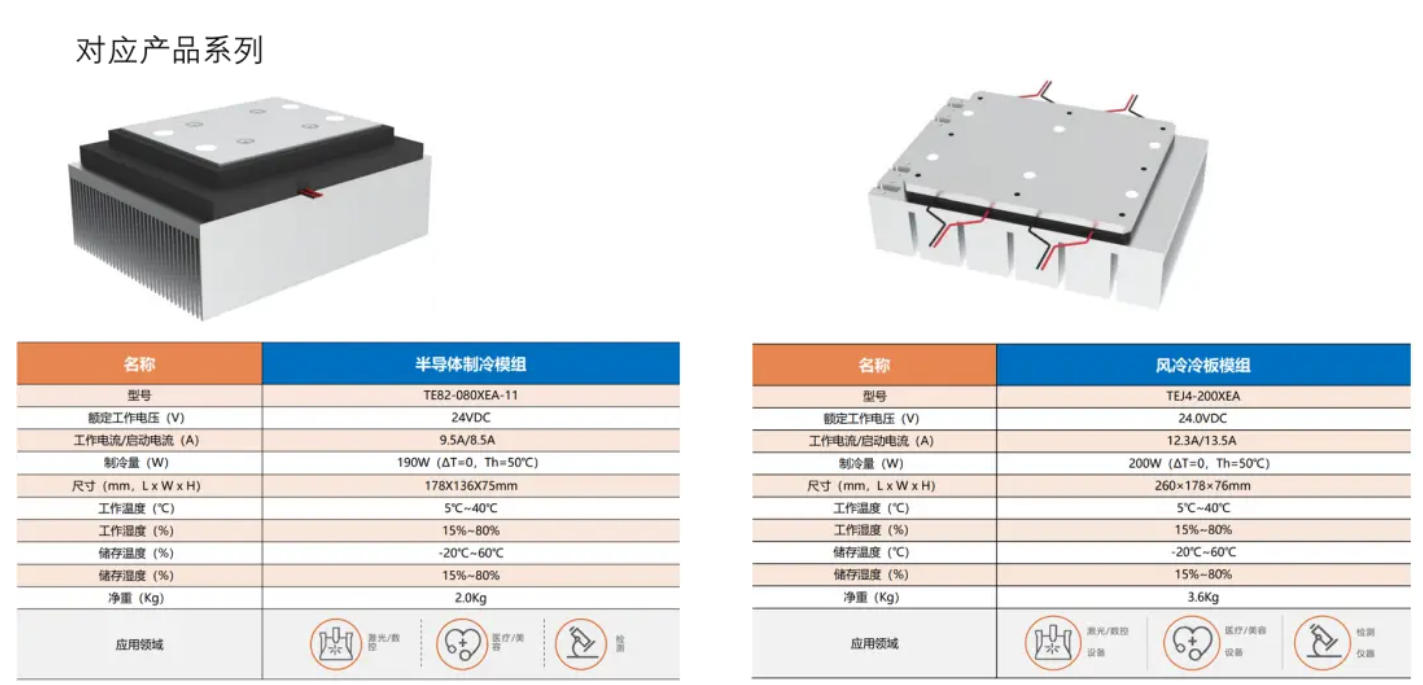

Semiconductor Cooling Modules by Huajing Temperature Control for the IVD Medical Device Industry

![]() Contact Our Thermal Experts:

Contact Our Thermal Experts:

📞 +86 18575222950 (WeChat/WhatApps)

📧 EMAIL: sale02@hj-tc.com

🌐 Browse products: https://www.huajingtc.com (Huajing Cooling Solutions)

Optimize your UAV & Laser & Beauty system's performance with Huajing's advanced thermoelectric cooling technology.

Looking for more

information?

0755 23405284

Email: sale02@hj-tc.com

Add: 3/F No.5 Building,Yesun Pingshan Life and Health Technology Park, No. 19 Linhui Road,Pingshan District, Shenzhen, Guangdong,CN.

©2019- 2024 Huajing Co.,Ltd.Copyright