Release time: September 22, 2025

Views: 542

Have you ever wondered how some mini refrigerators can cool without a compressor? The answer lies in a remarkable electronic component—the semiconductor cooling plate. In this article, HuaJing Temperature Control will take you on an in-depth exploration of how this "magic ice cube" of modern technology works. Let’s dive into the principles of semiconductor cooling plates!

A semiconductor cooling plate (Thermoelectric Cooler, or TEC) is a solid-state electronic device that achieves cooling based on the thermoelectric effect. It typically looks like a small ceramic square, a few centimeters in size and about 3-5 mm thick. Though seemingly unremarkable, it delivers astonishing cooling performance.

Compared to traditional compressor-based cooling, semiconductor cooling plates offer unique advantages:

1.No moving parts, completely silent operation.

2.Compact size, enabling miniaturization.

3.Fast cooling speed and short response time.

4.Can switch between heating and cooling by reversing the current direction.

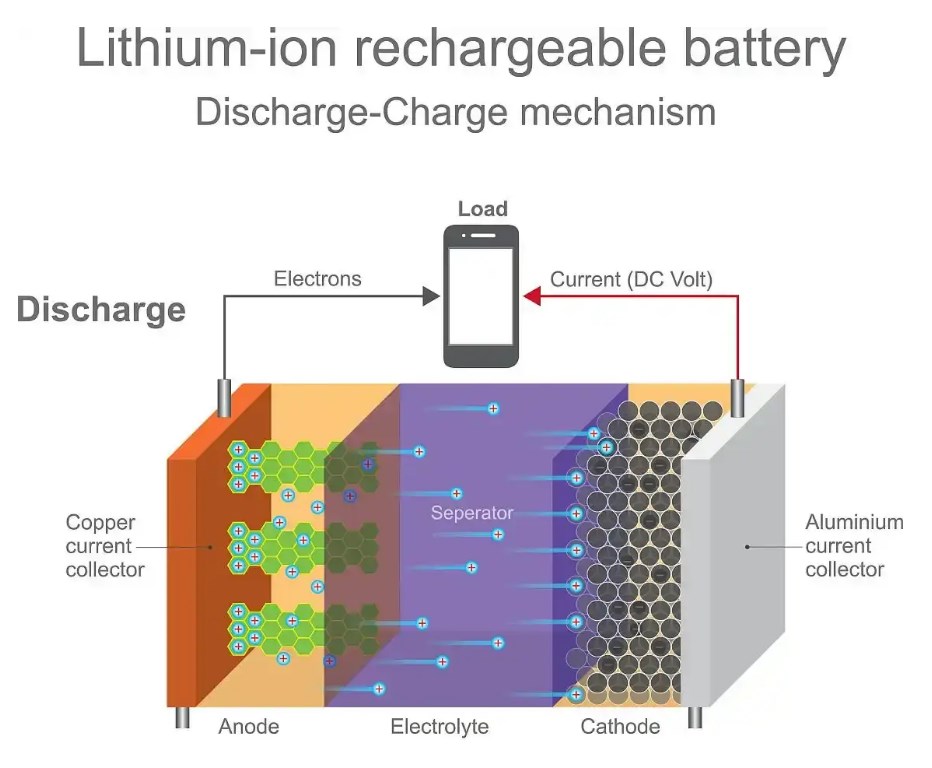

The working principle of semiconductor cooling plates is based on the Peltier Effect, discovered in 1834. This effect describes how, when an electric current passes through the contact point of two different conductors, heat is either absorbed or released at that junction.

Specifically:

When current flows from Conductor A to Conductor B, the contact point absorbs heat (cooling).

When the current flows in the reverse direction, the contact point releases heat (heating).

The amount of heat transferred is proportional to the current intensity.

Why are semiconductors particularly suited for this application? The key lies in their unique electronic structure:

N-type semiconductors: Use electrons as the primary charge carriers.

P-type semiconductors: Use holes as the primary charge carriers.

When current passes through a PN junction, carriers need to absorb significant heat to jump to a higher energy level.

This energy exchange process is the essence of cooling/heating.

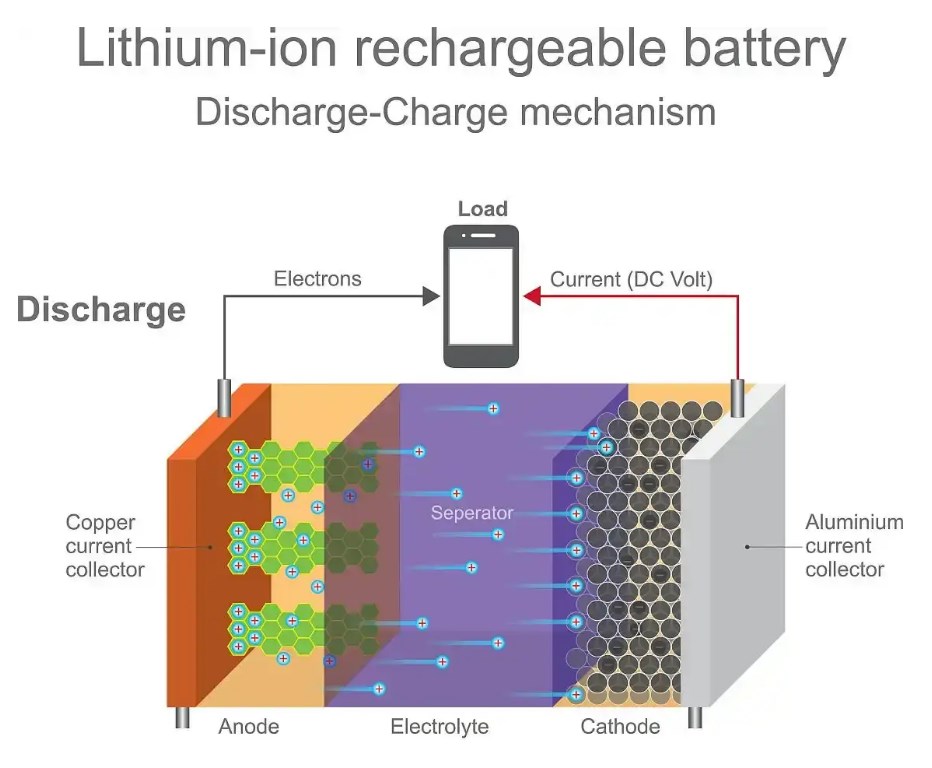

A typical semiconductor cooling plate consists of the following layers (from top to bottom):

Aluminum oxide ceramic substrate (insulating and thermally conductive).

Copper conductive layer.

Hundreds of PN semiconductor thermocouples.

Another copper conductive layer.

Bottom aluminum oxide ceramic substrate.

These components are connected via:

Series circuits linking all thermocouples.

Parallel structures to increase the cooling area.

Precision welding to ensure thermal conduction efficiency.

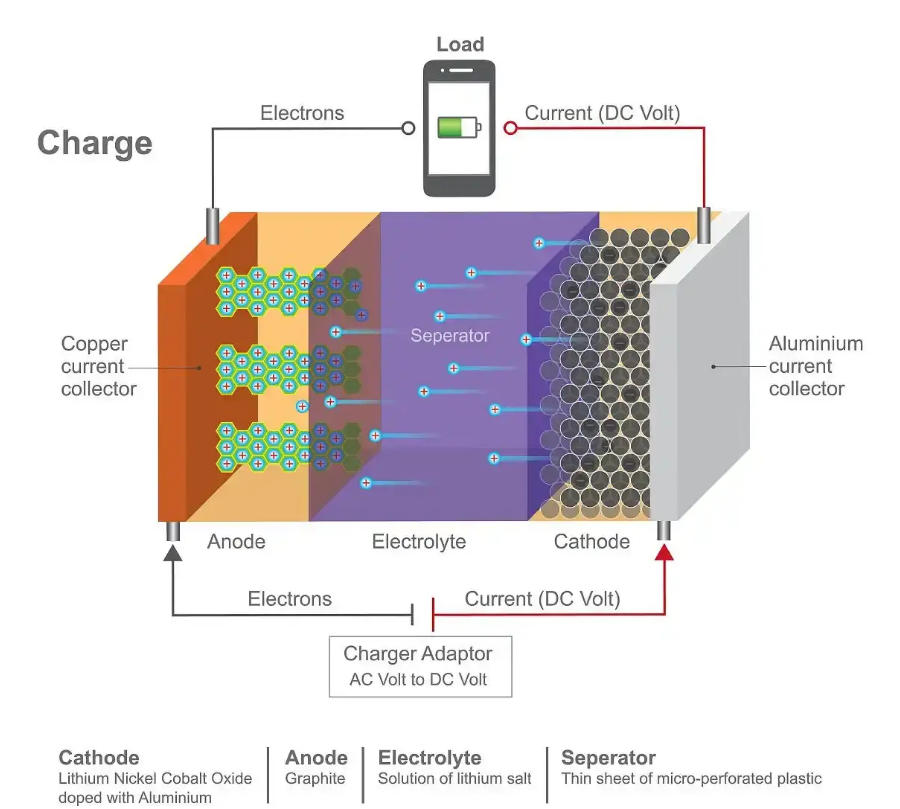

When direct current passes through the cooling plate:

As electrons flow from the N-type semiconductor to the P-type semiconductor, heat is absorbed at the contact point.

As electrons flow from the P-type semiconductor to the N-type semiconductor, heat is released at the other contact point.

Through this directional heat transfer, one side becomes cold while the other becomes hot.

Heat is "pumped" from the cold end to the hot end, with a temperature difference of up to 60-70°C.

The efficiency of semiconductor cooling plates depends on several factors:

Material quality: Bismuth telluride (Bi₂Te₃) is currently the best choice.

Number of thermocouples: More pairs mean greater cooling capacity.

Current intensity: Must operate near the optimal working point.

Heat dissipation conditions: Effective hot-side heat dissipation is critical.

Ambient temperature: High temperatures reduce efficiency.

This unique cooling method is widely used in:

Precision instrument temperature control (e.g., lasers, CCD sensors).

Car refrigerators/mini refrigerators.

Electronic device cooling (e.g., auxiliary CPU cooling).

Medical equipment (e.g., portable medicine refrigerators).

Aerospace applications (reliable cooling in zero-gravity environments).

Behind the seemingly simple principle of semiconductor cooling plates lies the accumulated wisdom of years of research. They demonstrate the immense potential of solid-state thermal management. This "electronic ice cube" is gradually revolutionizing the way we approach cooling. The next time you use a mini refrigerator, think about the thermodynamic magic happening inside those tiny semiconductor components!

About HuaJing Temperature Control Technology Co., Ltd.

HuaJing Temperature Control Technology Co., Ltd. is a national high-tech enterprise specializing in temperature control equipment solutions, integrating R&D, production, sales, and service. The company focuses on three main areas: semiconductor cooling technology, vapor-compression refrigeration technology, and soft conductive heating film application technology. It provides comprehensive solutions including 3D structural design, CAE thermal simulation analysis, and electronic hardware and software support. Its products are widely used in medical equipment, beauty devices, laser equipment, communication and power systems, aerospace, new energy vehicles, and other industries.

![]() Contact Our Thermal Experts:

Contact Our Thermal Experts:

📞 +86 18575222950 (WeChat/WhatApps)

📧 EMAIL: sale02@hj-tc.com

🌐 Browse products: https://www.huajingtc.com (Huajing Cooling Solutions)

Optimize your UAV & Laser & Beauty system's performance with Huajing's advanced thermoelectric cooling technology.

Looking for more

information?

0755 23405284

Email: sale02@hj-tc.com

Add: 3/F No.5 Building,Yesun Pingshan Life and Health Technology Park, No. 19 Linhui Road,Pingshan District, Shenzhen, Guangdong,CN.

©2019- 2024 Huajing Co.,Ltd.Copyright